A reliable connecting component for electronic devices

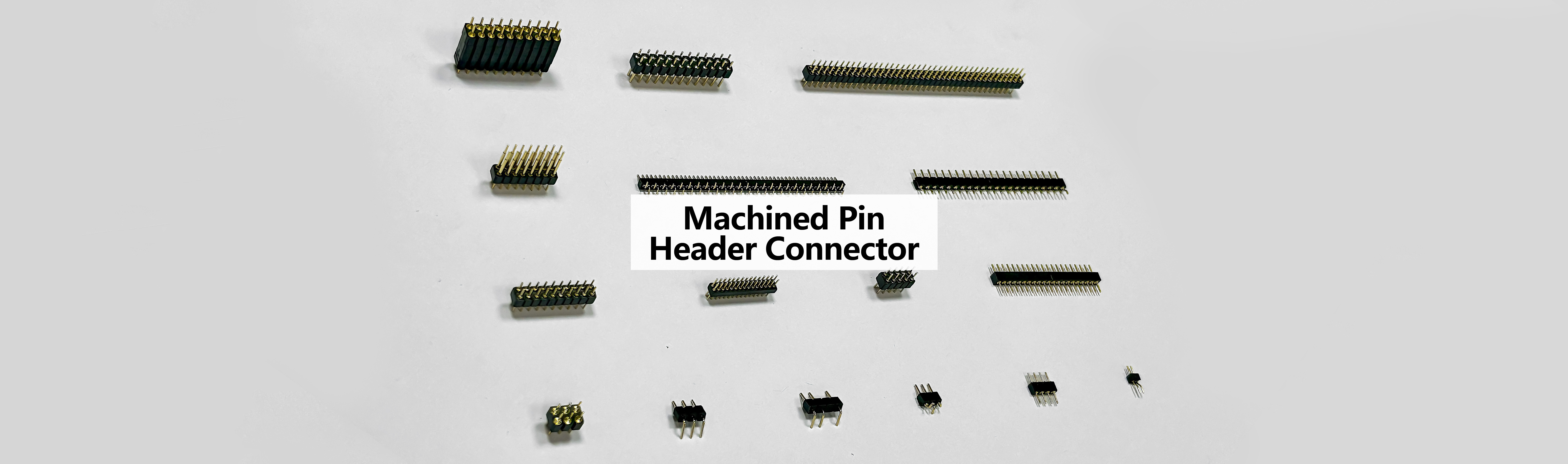

Machined pin header connector is a commonly used connecting component in electronic devices. The pin surface is mostly tin-plated or gold-plated to improve conductivity and anti-oxidation ability. It can also be selected with different pin counts and lengths according to device requirements, and is mainly used for signal and power transmission between circuit boards or between boards and components.

It consists only of round pins and plastic with circular holes, without complex components. Used with circular-hole headers, it can be mated without special tools, making it easy to operate.

The cylindrical pins match the circular holes, reducing insertion and extraction friction resistance. It operates smoothly while reducing pin wear, extending the service life of insertion and extraction.

Low contact resistance reduces signal transmission loss; high insulation resistance isolates external interference and avoids short-circuit risks, ensuring stable transmission of current and signals.

Denentech Machined PIN Header Connectors feature precise and stable pin mating, with both adaptability and reliability. They offer standard products and customization options, meeting the signal and power transmission needs of multiple fields such as industrial control and consumer electronics.

Contact nowFocus on precision small-pitch round pin headers, support high-density pin layout, fit compact consumer electronics like mobile phones and printers, match high-precision welding tech to meet narrow-space connection needs.

The core is a dual-row unequal-pitch round pin header (1.27mm horizontal + 2.54mm vertical), with UL94 V-0 high-temperature resistant shell, supports -40℃ to +105℃ wide temperature range, compatible with SMT/through-hole mounting.

Focus on medium-density round pin headers, balancing space utilization and current performance, with a rated current of up to 3.0A, suitable for scenarios like automotive electronics and medical equipment round pin headers, ensuring stable signal and power transmission.

Classic 0.1-inch standard-pitch round pin header, with large pin diameter and low contact resistance, supports manual soldering, suitable for education & research, DIY test boards, etc., easy to repair and debug.

1.778mm fine pitch precisely matches 28P-64P IC pins, ensuring stable chip test signals and simplifying chip replacement and development processes.

Covering industry, communication equipment, consumer electronics, etc., with stock, easy customization, cost-effective bulk purchase. Contact us for exclusive solutions.